Events

| 27th/28th of February 2018 | Kick-off Meeting at Profactor in Steyr | |

| 29th/30th of August 2018 | General Meeting at UNIPD in Padova | |

| 27th/28th of February 2019 | General Meeting & Demo #1 at CRF in Orbassano | |

| 18th/19th of June 2019 | General Meeting at Infratec in Dresden | |

| 5th of September 2019 | Review Meeting at CRF in Orbassano | |

| 19th/20th of February 2020 | General Meeting at FACC in Ried im Innkreis | |

| 23rd/24th of September 2020 | General Meeting at Marposs in Bentivoglio | |

| 17th/18th of February 2021 | General Meeting (virtual) | |

| 20th of April 2021 | Final General Meeting (virtual) | |

| 20th of May 2021 | Final Review Meeting (virtual) |

News

20th of May 2021. SPIRIT presents its final results

- A summary of the SPIRIT project in 90 seconds can be found here.

- A datasheet of the SPIRIT Software Framework can be found here.

- A set of operational data acquired during the tests can be found here.

Examples of implementation of the SPIRIT Offline and Inline Software Framework include:

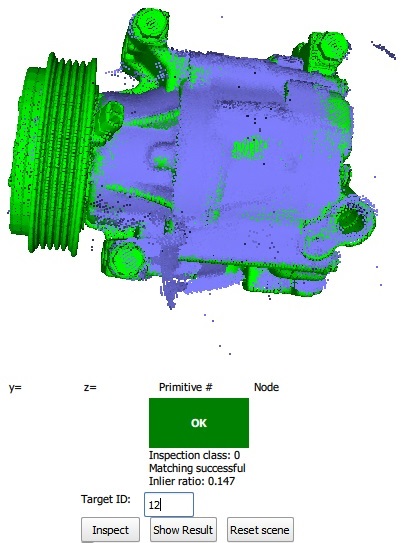

- The identification of assemblies in the automotive industry. Link

- The X-Ray inspection of composite parts in the aerospace industry. Link

- The thermographic detection of cracks in forged parts. Link

- The 3D scanning of large forged parts to detect folds and cracks. Link

17th/18th of February 2021. Virtual general meeting, Demonstrations to start

The SPIRIT project is now entering its final phase and a general meeting was held to plan the remaining months of the project. During the test on the use cases most developments could demonstrate good progress and were finished. A few of the more complex modules still require final developments for completion. Once all the modules are in place an extended evaluation and demonstration phase is planned. The efficiency of the offline and inline SPIRIT framework will be demonstrated on a total of 20 test cases. These test cases include a wide range of inspection technologies, several different brands of robots and a huge variety of automotive and aerospace parts. By completing the setup of all these test cases in just a few weeks, SPIRIT will demonstrate the efficiency of the tools that have been developed.

28th of January 2021. New video available, JEC scheduled for June 2021

After finishing the main features of thermographic crack detection (called use case #3A in the SPIRIT project) a new video is now available. The video shows the single components of the robotic workcell and explains how it links to the SPIRIT offline and inline framework. Alex Walch, our main developer of the inline framework will show you the details of this use case under this link. The SPIRIT project is now entering its final stages and the single components related to reactive path planning, image mapping and stitching are about to be finished. Weekly tests are currently done on the crack detection robot that was set up by partner Marposs and was transferred to project partner BSTG in autumn 2020. A demonstration is expected for the upcoming general meeting that is scheduled for mid February 2021. COVID has taken its toll on high quality dissemination activities. Nevertheless the partners are optimistic about having a final project presentation at the JEC World fair in Paris, which is now scheduled for 1st to 3rd of June 2021.

3rd of November 2020. Thermographic crack detection finished

A major demonstration could be successfully completed in the SPIRIT project. The SPIRIT framework has been integrated with a Fanuc Robot in a workcell used for the detection of cracks in forged parts. The inspection technology consists of a laser with about 100W of power and a thermo-camera that is acquiring about 30 frames per second in high resolution. An automatic path planning has been done using the SPIRIT offline framework to generate a trajectory that fully covers the camshaft that is to be inspected. The inspection task was executed by the SPIRIT inline framework and during this process about 40.000 images were acquired, synchronized with the robot’s motion and analyzed for cracks. Even though algorithm development for defect detection is not the main focus of the SPIRIT project, the false positive rate was remarkably low, while all cracks on the part could be detected. The main challenges of this use case included the quite complex inspection process and the accurate calibration and 3D modelling that was required to make sure that the part’s surface is always in focus of the laser spot and the camera at the same time. A video presentation of the use case will be made available in December 2020.

22nd of October 2020. Presentation on Path Planning

Project results related to path planning were presented at the Composites Virtual Summit from 19th to 22nd of October 2020, which included a sub-conference on “Composites Analysis and Testing”. The presentation included all aspects of path and motion planning developed in SPIRIT: Offline path planning, global re-planning to adapt to changes prior to inspection and reactive path planning to adapt to changes during the inspection. The conference was arranged as a virtual event, a recording of the 15 minutes presentation is available under this link.

23rd of September 2020. General Meeting, Demonstration and Exploitation

The long-awaited next general meeting of the SPIRIT project finally took place at Marposs near Bologna. Almost all partners could physically participate in this meeting, which was very well oragnized by Marposs and a maximum of safety was ensured for all participants. Seven months have passed since the last meeting and there was a densely packed agenda that already included planning of the project until its end in May 2021. A draft plan was made up including several integration meetings for setting up the demonstrators. Also, a plan for dissemination was made, given the current uncertainties related to such activities. The meeting lasted for 2 days and ended with a session on exploitation planning, where substantial contributions were made by the concerned partners. An intermediate demonstration of use case was made to all partners, which showed the robotic scanning of a forged part for crack detection.

19th of September 2020. Integration of Crack Detection Demonstrator

After a long period of remote integration work and tests it was finally inevitable to meet at Marposs in Bentivoglio near Bologna to set up the demonstrator prior to the upcoming general meeting. Various components were integrated, including the synchronisation of robot motion and data collection from the profile scanner, the calibration of the whole system and the offline trajectory planning. Also a deeper integration of the SPIRIT inline framework with the other components was achieved. Specific attention had to be paid to the fact that some of the data preprocessing is done in the controller unit of the sensor, which required additional interfaces and data conversion to fully integrate it into the SPIRIT framework. As always during such intermediate integration sessions a few additional technical topics came up that will have to be addressed in the following weeks. Nevertheless the demonstrator is in a good state and right after the general meeting it will be transferred from Marposs, where the integration took place, to BSTG, where the final demonstration is planned.

8th of September 2020. Best Paper Award for SPIRIT at ETFA 2020

The results achieved in the SPIRIT project related to 3D image mapping of X-Ray images of aerospace carbon fiber composite parts were presented as a scientific paper at the IEEE International Conference on Emerging Technologies and Factory Automation. The conference took place in early September 2020 and UNIPD, who prepared this paper jointly with IT+Robotics, are particularly proud to announce that they received the Best Paper Award in the “work in progress” category. Congratulations by the whole consortium!

20th of April 2020. Inspection robot for carbon fiber parts set up in half a day

While observing all necessary pre-cautions that applied in April 2020 an additional test of the SPIRIT software framework could be conducted in the laboratory of Profactor. The tests included the inspection of a draped carbon fiber part with Profactor’s FScan sensor. The SPIRIT inline framework (including the coverage and motion planning) was used to perform a full surface scan and to detect deviations in fiber orientation and other surface defects, such as foreign objects. The efficiency of the framework was demonstrated by the fact that two quite different inspection tasks could be set up in less than half a day.

3rd-5th of March 2020. SPIRIT project at JEC fair

The SPIRIT project will be presented at the JEC fair in Paris at the Profactor booth in Hall 6 Booth 75. Update: due to Corona-virus the JEC fair has been postponed to 2021.

19th of February 2020. X-Ray robot in action

In February 2020 the consortium met at project partner FACC in Ried im Innkreis to assess the progress and to demonstrate the recent developments. For the demonstration a huge robotic system for the X-Ray inspection of large composite parts was used. It consists of two synchronized robots, one holding the X-Ray source and the other one the detector. A collision-free path was planned automatically for the inspection of the part and was demonstrated live during the meeting at FACC. Additional features have been added to merge the acquired images into one large, colored and textured model of the part. Furthermore a reactive alignment of the robot was integrated, by analysing the X-Ray image of the hexagonal structure of the honeycomb core. This alignment is used to reactively adjust the inspection process so that the honeycomb structure is always shown in an optimal way.

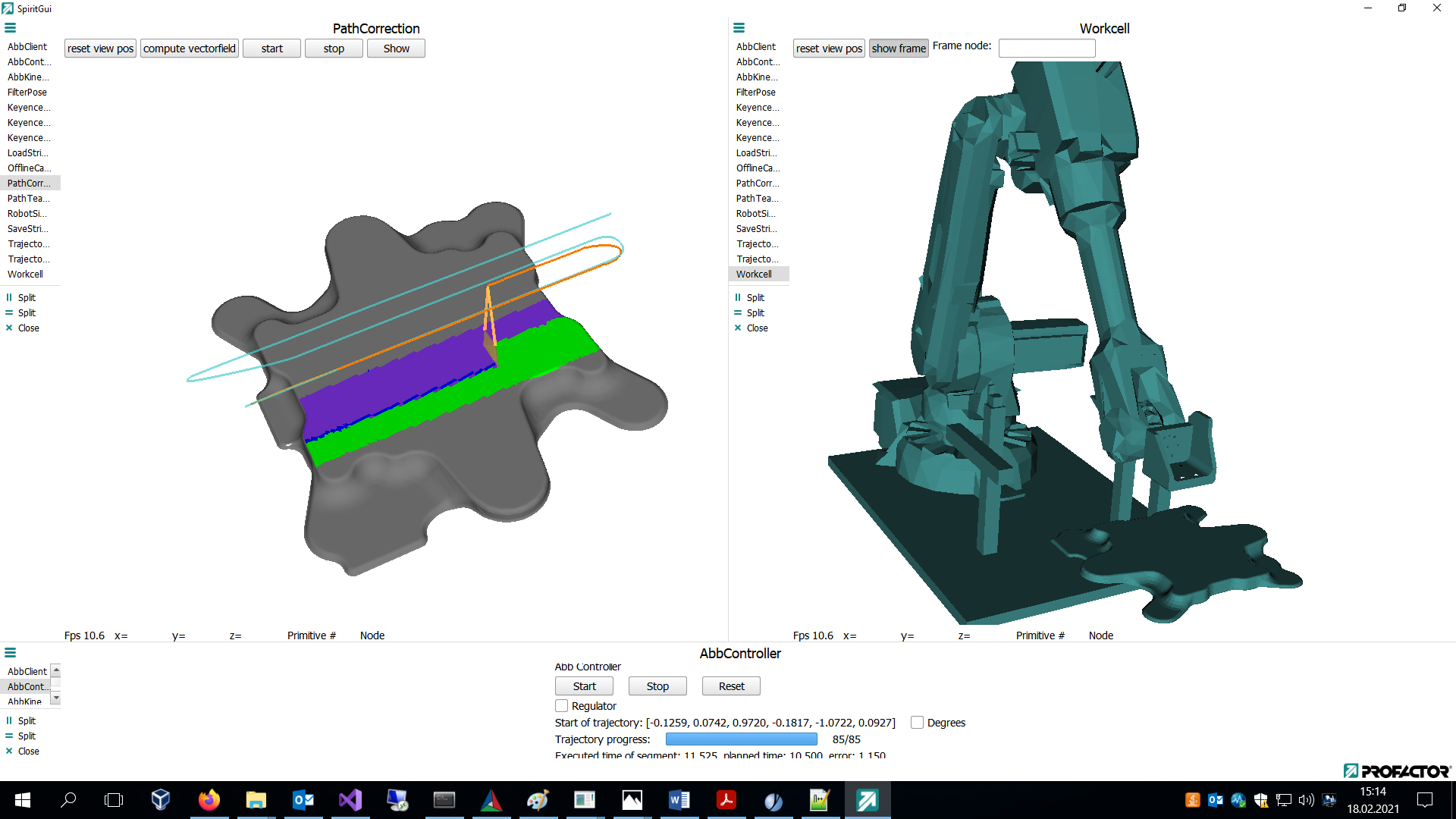

5th of September 2019. Plan your task in 25 minutes By the end of August the main part of the activities for path planning of the inspection were completed. Inspection paths for the robots have been calculated for all test cases based on their workcell and part models. During the evaluation a test was completed to check the time needed to set up an inspection task for a new type of part. Experiments showed that a user with average experience just needs 25 minutes to define an inspection path that fully covers the part and that can be executed on the robot. This was achieved using the enhanced workcell simulation software of partner IT+Robotics.

By the end of August the main part of the activities for path planning of the inspection were completed. Inspection paths for the robots have been calculated for all test cases based on their workcell and part models. During the evaluation a test was completed to check the time needed to set up an inspection task for a new type of part. Experiments showed that a user with average experience just needs 25 minutes to define an inspection path that fully covers the part and that can be executed on the robot. This was achieved using the enhanced workcell simulation software of partner IT+Robotics.

18th/19th of June 2019. General Meeting In June 2019 the whole consortium met at project partner Infratec in Dresden. The meeting was dedicated to the preparation of the periodic reporting and the upcoming review meeting. At the technical level the main focus was on the second test case with two synchronized robots carrying an X-ray sensor to inspect a carbon fiber composite part. The demonstration including this test case is planned for project month 26 (Feb. 2020) and will show key developments of the project, such as the automatic data mapping, where the images acquired by the X-ray sensor are mapped seamlessly to the 3D surface of the part. Major tasks related to automatic replanning of previously planned inspection paths are starting soon and the plans for the development of these features were discussed in detail. During the meeting Infratec offered a tour through their facilities, where partners could take a look at the different thermography systems built by Infratec and at their advanced calibration laboratory for temperature calibration of their thermographic cameras.

In June 2019 the whole consortium met at project partner Infratec in Dresden. The meeting was dedicated to the preparation of the periodic reporting and the upcoming review meeting. At the technical level the main focus was on the second test case with two synchronized robots carrying an X-ray sensor to inspect a carbon fiber composite part. The demonstration including this test case is planned for project month 26 (Feb. 2020) and will show key developments of the project, such as the automatic data mapping, where the images acquired by the X-ray sensor are mapped seamlessly to the 3D surface of the part. Major tasks related to automatic replanning of previously planned inspection paths are starting soon and the plans for the development of these features were discussed in detail. During the meeting Infratec offered a tour through their facilities, where partners could take a look at the different thermography systems built by Infratec and at their advanced calibration laboratory for temperature calibration of their thermographic cameras.

24th of May 2019. Developments proceed Developments are quickly proceeding in several aspects of the project. Path planning and robot program generation modules have been improved to allow a quicker and smoother motion of the robot. This has already been installed and successfully tested on the demonstration setup at CRF. Furthermore the whole process of calibration has been assessed in great detail, characterizing the single influence factors from hand-eye calibration over robot accuracy to part positioning. All of the these elements build the basis for the accurate mapping of the acquired data onto the 3D model of the parts. First steps have also been taken to integrate the second demonstration, an X-Ray inspection system consisting of two robots that is setup at project partner FACC. Hardware interfaces for robot control and X-Ray image acquisition are currently being implemented and tested.

Developments are quickly proceeding in several aspects of the project. Path planning and robot program generation modules have been improved to allow a quicker and smoother motion of the robot. This has already been installed and successfully tested on the demonstration setup at CRF. Furthermore the whole process of calibration has been assessed in great detail, characterizing the single influence factors from hand-eye calibration over robot accuracy to part positioning. All of the these elements build the basis for the accurate mapping of the acquired data onto the 3D model of the parts. First steps have also been taken to integrate the second demonstration, an X-Ray inspection system consisting of two robots that is setup at project partner FACC. Hardware interfaces for robot control and X-Ray image acquisition are currently being implemented and tested.

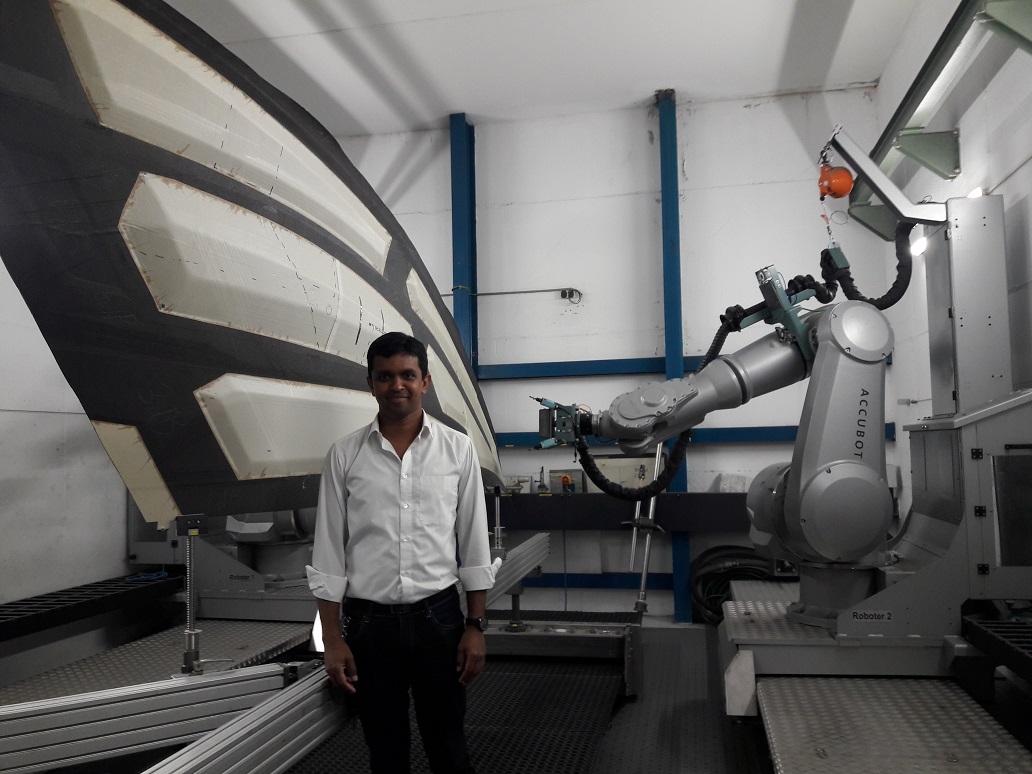

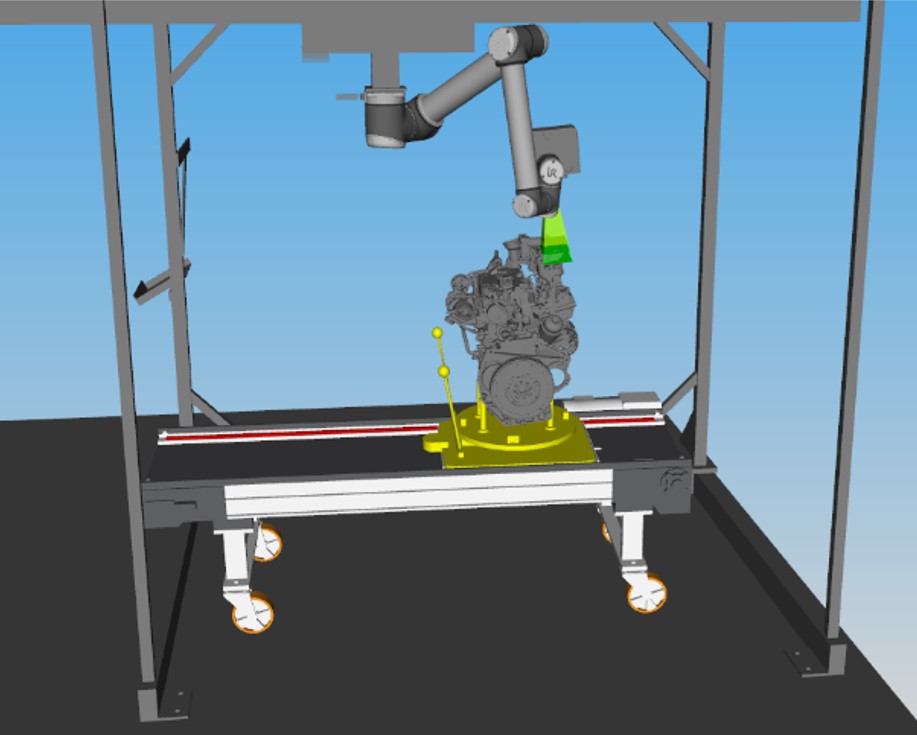

27th of February 2019. Demonstration #1 In the months prior to this meeting significant effort was spent on setting up a complete demonstration at CRF in Orbassano (Torino). The task of the robot is to inspect a number of critical features on the engine, such as missing or misplaced components. As an additional challenge the engine was moving on a conveyor belt during the inspection process. This made the path planning somewhat difficult, especially because an automatic adaptation based on the current position of the engine was already integrated. The demonstration was completed successfully and followed by a detailed evaluation to assess the performance relative to the technical goals set for the end of the project. Good progress was made in all aspects and demonstration #1 actually exceeded the plans made for this stage of the project. The second day of the general meeting was also spent on discussing initial plans for the exploitation of the project results and to obtain a more accurate estimation of the exploitation potential.

In the months prior to this meeting significant effort was spent on setting up a complete demonstration at CRF in Orbassano (Torino). The task of the robot is to inspect a number of critical features on the engine, such as missing or misplaced components. As an additional challenge the engine was moving on a conveyor belt during the inspection process. This made the path planning somewhat difficult, especially because an automatic adaptation based on the current position of the engine was already integrated. The demonstration was completed successfully and followed by a detailed evaluation to assess the performance relative to the technical goals set for the end of the project. Good progress was made in all aspects and demonstration #1 actually exceeded the plans made for this stage of the project. The second day of the general meeting was also spent on discussing initial plans for the exploitation of the project results and to obtain a more accurate estimation of the exploitation potential.

07th of December 2018. First Integration Test

In the first week of December 2018 Profactor, TI+Robotics and Marposs gathered at CRF for a first integration of the SPIRIT developments. This initial test dealt with the task of automating the inspection of an assembled engine on a moving conveyor belt. The integration was targeted on testing the single components such as the 3D sensor, the calibration, the synchronization of robot motion and data acquisition and the offline motion planning. The setup was well prepared by CRF and only a few issues related to the interfaces between the partners had to be resolved before first tests could be done. The results indicated that there is good progress in all aspects. Improvements are still needed in relation to hand-eye calibration and at the interface to the conveyor’s control unit (to avoid collisions in case of a system failure). For hand-eye calibration the new algorithm just developed by University of Padova will be integrated and tested in the CRF facility. Overall the developments are in a good state and the project is well on track for the first demonstration that is scheduled for end of February 2019.

24th of October 2018. SPIRIT Inspection Technologies.

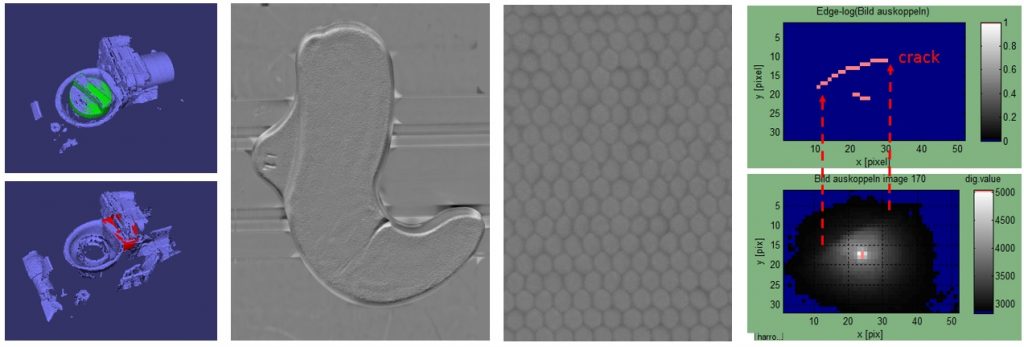

The SPIRIT project at a generic solution for a wide range of image-based inspection technologies. After a detailed investigation of the various test cases considered in the project first test have been made. All the technologies are assessed with a particular focus on their use in conjunction with robots and continuous scanning.

The inspection technologies include the inspection of assemblies using 3D point clouds, the detection of surface cracks on forged parts, the X-ray inspection of honeycomb cores in composite parts and the thermographic detection of surface-near cracks in forged parts (from left to right).

For all of these technologies process models have been developed that will now be used for the automatic path planning to scan the whole part.

29th/30th of August 2018. M08 General meeting. Right after summer vacation the consortium met in Padova where the general meeting was hosted by partner UNIPD. The meeting was dedicated to finalizing the definition of the use cases that are being investigated in the project with the goal of deducing a generally applicable software framework. The modelling of the inspection processes and the collection of CAD data of test parts and workcells has made significant progress. Tests with different inspection technologies have been made to confirm the suitability of the technologies for the single test cases. At the end of the meeting a demonstration was made by UNIPD to show the recent process in terms of hand-eye calibration and temporal synchronisation of robot motion and image acquisition.

Right after summer vacation the consortium met in Padova where the general meeting was hosted by partner UNIPD. The meeting was dedicated to finalizing the definition of the use cases that are being investigated in the project with the goal of deducing a generally applicable software framework. The modelling of the inspection processes and the collection of CAD data of test parts and workcells has made significant progress. Tests with different inspection technologies have been made to confirm the suitability of the technologies for the single test cases. At the end of the meeting a demonstration was made by UNIPD to show the recent process in terms of hand-eye calibration and temporal synchronisation of robot motion and image acquisition.

27th/28th of February 2018. Kick off meeting.

The SPIRIT project had its first meeting at Profactor in Steyr. At freezing temperatures below -10° the whole consortium met to discuss the first steps in the project. A detailed presentation of the various test cases and their challenges was followed by a planning process that covered the next 6 to 9 months. All partners provided substantial background in their fields and – due to past collaborations – a smooth start of the project could be achieved. Already at this stage the main interfaces could be clarified and a common understanding of the main goals and the next steps was achieved.

The SPIRIT project had its first meeting at Profactor in Steyr. At freezing temperatures below -10° the whole consortium met to discuss the first steps in the project. A detailed presentation of the various test cases and their challenges was followed by a planning process that covered the next 6 to 9 months. All partners provided substantial background in their fields and – due to past collaborations – a smooth start of the project could be achieved. Already at this stage the main interfaces could be clarified and a common understanding of the main goals and the next steps was achieved.

2nd January 2018. The project SPIRIT is started. The project’s web page has been set up.